1799

5

4 Reasons Why You Should Automate Your Warehouse

Have you ever faced a standstill when your manager calls in sick? Are broken promises with clients a regular issue? Do you struggle with managing warehouse order peaks?

We’re here to highlight three seemingly harmless issues that can snowball into major headaches and explain how the Warehouse Management System could prevent these problems.

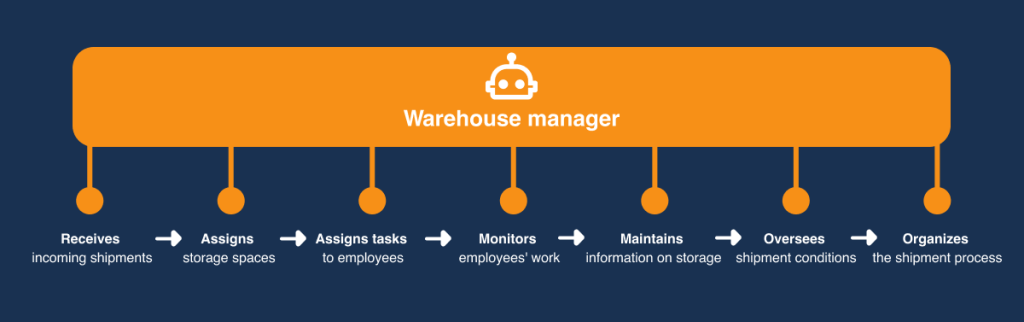

1. Dependency on a single person

Over time, a key figure may emerge in the warehouse. This person knows the whereabouts of every item, oversees employee tasks, handles incoming goods, and coordinates shipments.

This person could be your warehouse or section manager. He might have everything under control, even with his own tailored system

The manager handles all operations according to his own approach. It may function, but only the manager truly gets it.

Dependence on a single person can become a problem. What if the worker decides to move on?

If that were to happen, the warehouse could face a crisis: operations would grind to a halt, mistakes would crop up, and customers could be lost. Hence, the business remains ever vulnerable, always prepared to meet any demands from the manager.2. High risk of human mistakes

Let's say the business is fortunate, and the warehouse manager values and enjoys his work and doesn’t plan to leave. However, this doesn't exempt it from the human factor.

The capabilities of one individual are limited. The manager may strive to implement improvements and streamline processes, but he faces limitations:

-

Narrow perspective. A specialist may be familiar with a few best practices for organizing processes. For example, he may understand how to structure information in Excel. However, one tool and the skills of one person usually fall short of the capabilities of modern advanced interfaces and systems.

-

Employee turnover. The manager works in a warehouse with a large number of people who require close supervision: some are not sufficiently engaged, some have just arrived and do not yet understand the processes, and some find it difficult to remember the work regulations. As a result, the manager has to spend a lot of effort on monitoring. And ensuring 100% control is still impossible.

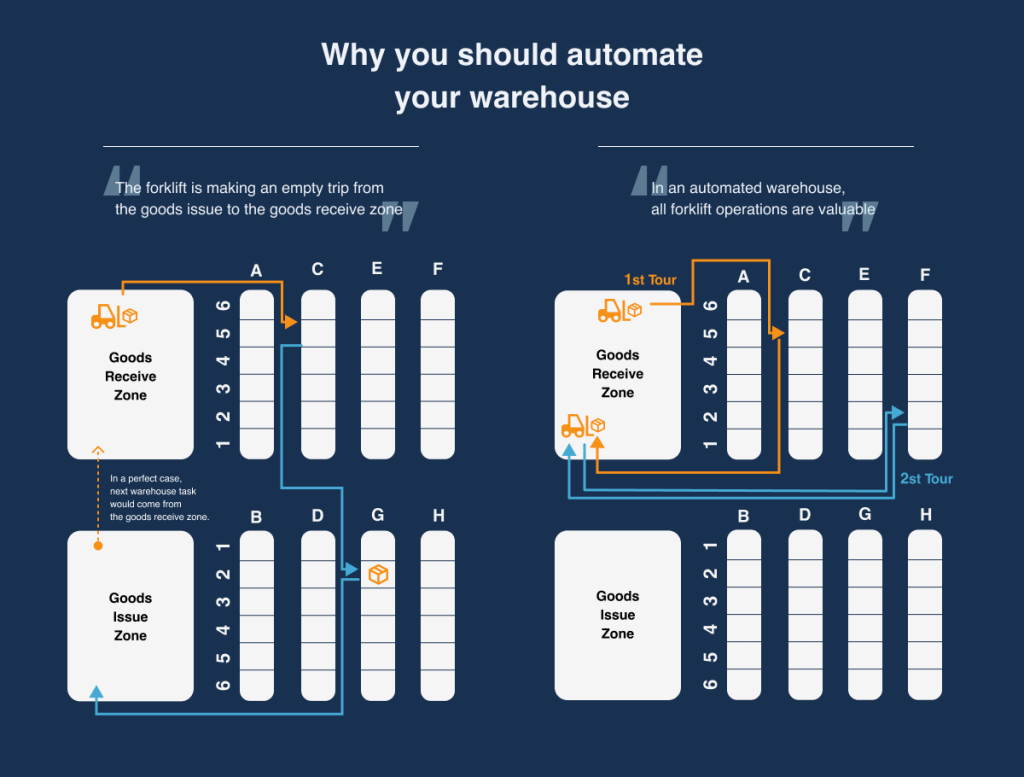

As a result, there are losses and inefficiencies. For example, when a forklift makes an empty trip.

Manager cannot independently plan and supervise every movement of the workers. This leads to time losses, affecting the speed of operations and the quality of services for customers.

As a result, you find yourself in a challenging situation: you need to motivate the manager to increase efficiency while also trying to assess the unpredictable risks of the human factor and, based on them, negotiate with customers.

3. Limited Scalability

As the business grows and SKU number increases, manual operations become cumbersome and less effective. Some businesses choose to hire more workers to manage the growing SKUs, but it’s not always a working strategy.

Here’s an example. One of our customers, a mid-sized manufacturer of electronic gadgets and accessories, experienced rapid growth, expanding its product line to include thousands of different SKUs.

Initially, they managed their warehouse operations manually, relying on spreadsheets to track inventory, fulfill orders, and manage stock levels. But in a while they’ve faced some serious challenges.

Managing a growing number of SKUs required more manual labor and drove up the operational costs. The business experienced frequent stockouts and overstocks due to insufficient inventory tracking. Without a systematic approach, the warehouse layout was chaotic, with items placed haphazardly, the space was used ineffectively and the staff was struggling with finding items.

To address these challenges the company decided to implement a Warehouse Management System (SAP EWM), providing automated inventory tracking, optimized storage solutions, and streamlined picking and receiving processes.

As a result of the implementation, they’ve increased inventory accuracy up to 99%, reduced the order fulfillment time by 25% and increased the storage capacity by 30%. Overall operational costs were reduced by 20% due to decreased labor costs and the business was able to scale up their operations and expand the product line.

4. Broken promises

A warehouse that relies heavily on just one person and his system for managing staff and risks can handle small volumes and SKU counts.

However, as the workload grows, cracks in the processes become more apparent. Handling volumes manually becomes tougher, leading to unpredictable spikes and a bunch of inventory errors.

This ends up lowering the quality of customer service — agreements the warehouse can't keep start cropping up. Not the most uplifting sight, is it?

Automation is the solution

No matter if you've identified one problem or all three in your business. Automation helps solve them.

-

Eliminates dependence on one person. The system stores all data in one place and automatically controls operations. As a result, processes are not reliant on one individual, and the business doesn't have to adjust to a specialist or bear high risks

-

Reduces the number of staff errors and optimizes processes. The system helps minimize the consequences of high turnover and low employee engagement. In an automated warehouse, each employee performs very clear, simple, and routine tasks. Decisions are made by the system.

Moreover, it reduces the need for supervision. For example, during picking, you can ask an employee to confirm that he's taken a specific product in the required quantity – let’s say 10 identical chocolate bars. You could insist that the worker scan each chocolate. However, supervising this is challenging, as it's easier for the employee to scan one bar ten times (and this is what usually happens in real life). The system eliminates the need for this supervision. It automatically tracks the movement of each item and confirms its arrival at the correct location. -

Enables forecasting and keeping promises. This is crucial.

If you keep your promises, customers see a reliable partner they can build long-term productive relationships with.

Key takeaways

-

Dependency on a single person

Reliance on a one key individual can disrupt warehouse operations. A WMS reduces this dependency by storing and dividing the warehouse tasks automatically. -

High risk of human mistakes

Errors in manual operations lead to increased costs. Automation minimizes these mistakes by standardizing warehouse processes. -

Limited Scalability

Manual management becomes inefficient as businesses grow. WMS improves overall accuracy and enables scalable growth. -

Broken promises

Manual processes often lead to delays and errors in orders, affecting customer service. Automated Warehouse Management Systems help businesses fulfill order commitments and maintain customer loyalty. - If you want to start transforming your warehouse with implementing a modern WMS solution, but don’t know where to start, contact us. Let’s begin your SCM journey!