1865

7 min

Case Study: How Top Russian Retailer Magnit Increased Forecast Accuracy and Availability While Reducing Stock by up to 17%

About Magnit

Magnit is Russia’s second-largest grocery retailer with 29,165 stores, over 38 distribution centers operating across 10 time zones, and more than $30 billion in annual revenue. Beyond grocery, Magnit operates production facilities for private label products, pharmacies, drugstores, and is expanding into e-commerce. The company is listed on the Moscow Stock Exchange and employs more than 368,000 people. Magnit’s strategic goal is to increase market share while maintaining business profitability, with a modern digital scalable platform as a key enabler of this strategy.

In 2020, the company faced several challenges while supporting its growing store network and implementing a logistics transformation strategy:

- Improving customer experience in Fresh categories, a core component of their market expansion strategy

- Efficiently managing increasingly complex supply chains

- Increasing the accuracy of promotion planning

- Coordinating assortment management, forecasting, and replenishment across multiple store formats

- Supporting growing e-commerce volumes

Simultaneously, Magnit was operating with a fragmented IT landscape including several legacy systems for core processes (e.g., three separate Forecasting & Replenishment systems: one for stores from 2003, another for DCs from 2012, a third for promotions, and an additional system for fruits and vegetables from 2017). The backlog of requested features had grown to 850, resulting in a five-year implementation horizon. Data flows between different F&R solutions had become intricate, making it difficult and resource-intensive to ensure data consistency and accuracy.

It became clear that these challenges could not be addressed through isolated enhancements. A comprehensive new approach was needed.

Project Goals and Approach

Magnit established the following project KPIs:

- Improved on-shelf availability at stores

- Reduced stock levels at stores and DCs

- Reduction of write-offs due to expiration

Since these KPIs were strongly related to stock management, the primary goal of Magnit’s digital transformation project was defined as:

To decrease stock at stores and DCs while maintaining high on-shelf availability of products.

Requirements from Commerce, Operations, and Finance departments were gathered and analyzed to consolidate the necessary features for the future F&R solution and shape the desired project team profile.

System requirements:

- Configurable: minimize configuration efforts while ensuring high controllability. Enable the addition of new functional modules while maintaining a flexible and modern IT architecture.

- Fast Time-to-Market: reduce the timeframe from new business requirement identification to implementation. Fast innovation implementation became crucial for retail following supply chain disruptions and e-commerce market changes after COVID-19.

- Integrated Planning: synchronize short-term and mid-term forecasts and plans. Ensure seamless and integrated planning across all product categories and store formats.

- Consolidated: implement a unified F&R platform for all sales channels including e-commerce, all store formats, DCs, and all product categories, including pharmaceuticals and non-food items (e.g., cosmetics).

- KPI-Focused: the system should serve as an instrument for improving defined business KPIs (on-shelf availability, stock level).

All potential vendors from the Gartner® Magic Quadrant™ for Supply Chain Planning Solutions leaders were evaluated against these five criteria.

Ultimately, Relex Platform was selected based on its high fit score, more than 500 implementation cases, and strong international references from major retail companies.

Team Structure

Once the IT solution was chosen, Magnit needed an implementation partner capable of providing both business process change support and Relex platform implementation and customization. TeamIdea was selected as the implementation partner based on:

- One of the strongest Supply Chain Management practices in the CIS region (more than 25 projects in supply chain implementation since 2015).

- Proven ability to handle and manage large complex projects for top companies (200+ digital transformation projects).

- International project experience as a member of United VARs SAP Partner Alliance

TeamIdea was chosen by Magnit as the key implementation partner for the project, forming a team of 85 members consisting of Magnit IT and business representatives, TeamIdea team members, and Relex specialists. Each party contributed to the project's success:

- TeamIdea was responsible for overall project management, delivery, consulting, user support, system configuration, and advanced model fine-tuning to achieve KPIs

- Relex led technical solution architecture, platform enhancements, and knowledge transfer to project team members. They also handled project quality assurance and provided expert consulting on advanced system configuration topics.

- Magnit managed platform integration with the existing IT landscape, data preparation, and migration—crucial for the successful launch of the F&R solution. Magnit business users clarified business requirements, product category specifics, and made business decisions on system configuration options and exceptions.

The project team was organized into three groups focused on main product categories:

- Dry: Products with relatively stable sales and long shelf-life

- Fresh: Products with short shelf-life and volatile sales

- Fruits & Vegetables: The most complex category for stock management with extremely short shelf-life, shrinkage effects, and high write-offs

Additionally, the project included sub-teams:

- Management: Responsible for project management and administration

- Architecture: Overseeing business process design and technical architecture to ensure scalability and system performance

- Integration & Data: Designing data flows and providing high-quality, validated data for calculations

- Promotion: Managing promotion forecasting and planning, which required special configuration efforts and significantly impacted overall sales forecast accuracy

The project team included not just IT specialists but also business experts from top regional retail and FMCG companies. Roles within the Magnit’s team included product owners, experts, business analysts/consultants, functional consultants, technical consultants, and developers.

This product-oriented team structure enhanced efficiency in reaching project KPIs and facilitated transparent business-oriented communication. For example, the Fruits and Vegetables category manager could communicate directly with the relevant sub-team and be easily understood since teams were formed based on business experience and background.

Functional & Organizational Scope

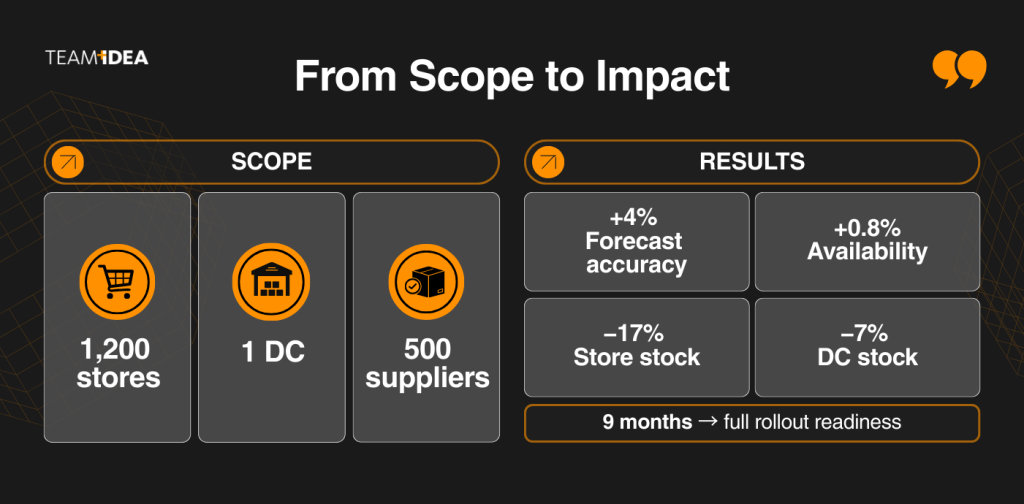

The project pilot covered 1,200 stores, one distribution center, 500 suppliers, and various product groups including fresh assortment.The project covered the following business processes:

- Management of assortment and stock for different store formats

- Collaborative promotion planning

- Supplier relationship management

- Sales and operations planning

Functional scope:

- Audit of existing forecasting and replenishment processes and data warehousing architecture; creation of a readiness map for digital transformation

- Implementation of a unified forecasting and replenishment solution, covering all store formats and product categories

- Distribution features implementation, including balancing inventory among stores based on capacity

- Integrated Supply Chain management, including tools for supplier delivery scheduling, service level tracking, and optimization of supplier interaction parameters

- Promotion planning and cannibalization analysis

- Fresh item optimization

- Store application development

- Collaborative supplier planning

Project Results

Implementation proceeded step-by-step by product category and store. Within 9 months after project initiation, the F&R system was ready for extensive rollout.

The results of the pilot project:

- +4% improvement in forecast accuracy at the store type-SKU-day level

- +0.8% increase in store-level availability

- -7% reduction in DC stock levels

- -17% reduction in store stock levels

These figures demonstrate significant reductions in losses due to spoilage, stock surplus, and lost sales from stockouts. Additionally, Magnit's planners reported satisfaction with the modern web-based interface and convenient tools for stock analytics, alerts, and order proposal reviews. Their daily routine transformed into lean, system-supported expert analysis, leading to more efficient replenishment processes and higher expertise levels.

Testimonials

“The key idea we want to instill in the business is continuous improvement. Not only should the project and project team succeed, but a culture of change must be created where system features are configured rather than just developed, business processes evolve, and data is continuously cleaned, updated, and enriched. This should happen in real-time and become a company focus for achieving our aims: stock reduction and on-shelf availability improvement. When the project ends, we want business operations personnel to efficiently manage these changes as small projects for the company's benefit.”

Egor Aleshin, Lead of Magnit’s F&R program

“The project scope included regular forecasting, replenishment, integrated supply chain, distribution, promotion forecasting, and fresh optimization. It was an ambitious project: 200 team members involved, 5 different store formats, more than 20,000 stores planned for rollout. The increase in availability rate and reduction of stock—the results we achieved—were possible only thanks to strong synergy between TeamIdea and Magnit’s teams.”

Olga Nikolaeva, Head of Planning and Forecasting (YWIS), TeamIdea.

Next steps

If you're interested in more details about the Magnit case or achieving similar results for your business, please contact us to arrange a detailed expert session for building an optimal digital transformation roadmap for your organization.Key takeaways

- Magnit, Russia's second-largest retailer, faced challenges in supply chain management related to business growth and a siloed IT landscape for F&R processes. The company selected Relex as its platform for orchestrating F&R processes and improving key business KPIs.

- The pilot project was executed by a joint team from Relex, TeamIdea-YWIS, and Magnit, resulting in improved forecast accuracy while reducing stock levels by up to 17%. The project methodology was based on Agile principles, with initial business benefits realized just 8-9 months after project initiation.