3520

8 min

How Relex Helps CPG Producers Boost Revenue with Smarter Demand Forecasting and Leaner Planning

Why Planning Is the New Growth Engine for CPG

The world of CPG spans everything from perishable dairy to durable household appliances. But whether you're moving yogurt by the truckload or placing electric razors on the store shelves the rules of the game are the same: mass production, low margins, high volumes — and zero room for error.

In this high-pressure environment, success hinges on one thing: demand. CPG brands thrive or fall based on how well they can align their production and supply chains to consumer needs. That means forecasting demand precisely, minimizing waste, and ensuring availability across increasingly fragmented channels — all while staying cost-competitive.

And this is where planning becomes business-critical. The scale of CPG operations generates massive datasets, and manual planning simply can’t keep up. Leading companies are turning to AI, big data analytics, and optimization engines to transform planning from a bottleneck into a strategic advantage.

The Relex Approach: Technology Built for Complexity

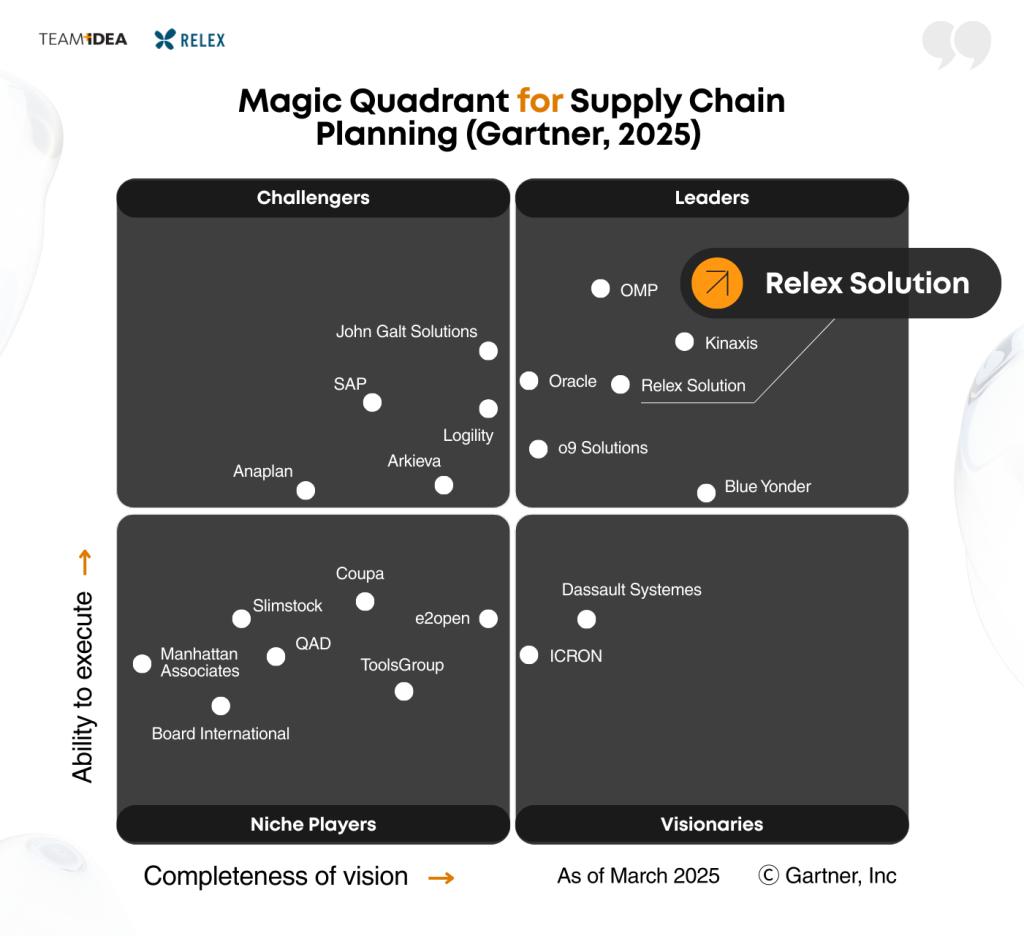

Relex Solutions is one of the frontrunners in this space. Recognized by Gartner as a Leader in the 2025 Magic Quadrant™ for Supply Chain Planning, Relex supports more than 600 companies worldwide with a suite of AI-powered tools for forecasting, production, inventory, promotion, and more.

Unlike generic platforms, Relex is purpose-built for the granular needs of CPG and retail. It models not just typical supply chain constraints, but also financial and ESG-related trade-offs. Its digital supply chain twin capability allows companies to simulate future scenarios and make better decisions today.

And it doesn’t stand still. With 25% of its revenue reinvested in R&D, Relex is advancing the frontier of AI — including specialized forecasting models and its own generative AI assistant, Rebot, embedded across the solution suite.

Market Trends Forcing Smarter Supply Chains

Why is this shift to intelligent planning so urgent? Because the rules of the CPG market are being rewritten — fast.

Short-term disruptions are now constant. Consumer behavior is shifting toward hard discounters and price-sensitive buying. Inflation is driving up input costs. Private labels are on the rise, chipping away at brand loyalty. Meanwhile, omnichannel retail — particularly e-commerce — adds new layers of complexity to fulfillment and demand shaping.

According to NielsenIQ, 67% of consumers are willing to try a new brand if the price is right. Offline shopping trips have dropped 27% in four years. In the U.S., CPI hit 6.5% — double the long-term average — with no clear sign of stabilization.

At the same time, long-term forces are reshaping supply itself. Climate change has made agricultural sourcing more volatile. ESG mandates are pushing brands toward greener, leaner operations. And global instability is forcing supply chains to shorten and reshore, often at higher cost. According to NielsenIQ, 70% of consumers are willing to purchase energy-efficient products.

The message is clear: planning is no longer back-office — it’s a frontline differentiator.

What Relex Offers to CPG Companies

Relex’s solution stack helps CPG businesses optimize the entire planning cycle — from high-level business planning to real-time, SKU-level decisions. The solution portfolio of Relex for CPG consists of the following products:

- Demand Planning & Demand sensing. It starts with demand. Relex’s demand sensing engines analyze real-time signals to improve forecast accuracy — not just overall, but across promotions, seasons, and sales channels.

- Master planning. Advanced tool translates demand into executable production schedules to meet demand and target stock levels.

- Production scheduling. Creation of production operations plans down to seconds considering constrains.

- Distribution planning. Solution ensures optimized quantities calculation for each distribution link considering demand, network structure, capacities, sourcing rules, demand/supply penalties.

- Supply chain collaboration. Supply matches the plan. Relex supports collaborative planning with suppliers to align deliveries and avoid planning mismatches.

- End-to-end inventory planning. Inventory stays lean. End-to-end inventory optimization ensures that safety stocks are calibrated, replenishment is responsive, and working capital isn’t wasted on overstock.

- Channel planning. This solution gives possibility to calculate different forecasts for channels and provides possibility of dynamic channel inventory allocation.

- Promotion planning. Marketing is in the loop. Promotion planning, seasonal allocation, and markdown optimization help commercial teams make smarter offers — and operational teams prepare for them.

- Seasonal planning. AI-driven clearance and markdown optimization helps in accurate seasonal allocation and managing product lifecycle

- Integrated business planning. This platform supporting strategic business planning and operation supply chain planning, scenario planning through supply chain and what-if analysis for maximizing profits.

- S&OP, S&OE. Strategic decisions are de-risked. With S&OP, and what-if simulations, companies can test scenarios and prepare contingency plans that balance profitability and resilience.

The result? Up to 99% forecast accuracy, 85% fewer stockouts, 30% inventory reduction, and up to 50% less manual planning effort. These aren’t just tech stats — they’re business outcomes.

Real-World Impact: Finsbury and Blount

Finsbury Food Group: Planning for Complexity

Finsbury, one of the UK’s top bakery manufacturers, operates eight factories supplying cakes, breads, and snacks to major retailers. Facing a mix of short-shelf-life products and time-sensitive production steps like fermentation, the company needed precision planning at scale.Relex solutions Demand Forecasting and Production Scheduling delivered. The Functional scope of the project included following pillars:

- AI-driven demand forecasting

- Price optimization

- Scenario planning for supporting S&OP and IBP processes

- Advanced analytics

- Optimization of production scheduling taking into account labor, capacity constraints, sequencing rules, available materials

- Integration between demand and supply planning

- Integration with ERP

And during project execution multiple challenges were faced:

- Different types of production including time-sensitive processes like fermentation require careful solution design

- Project faced influence of pandemic demand outliers and supply chain disruptions

- For some period, users were working in 2 forecasting systems (legacy and Relex) for mitigating risks for business resulting in high pressure on users

- Adoption of users to AI-based advanced forecasting requiring higher data quality and new user experience

AI-based forecasting, automated scheduling, and scenario planning helped Finsbury cut net working capital by $2.15 million, improve service levels by 5%, and double planner productivity — all while navigating pandemic volatility and transitioning from legacy systems.

Blount Fine Foods: Fresh, Fast, and Flexible

In the U.S., Blount Fine Foods produces fresh soups and entrees across three plants, 16 warehouses, and seven shipping sites. With 1,500 SKUs and ultra-short shelf lives, the company needed to reduce waste without compromising service.By adopting Relex Demand Forecasting and Master Planning solutions Blount enhanced business operations under following functional scope:

- AI-driven planning tools for demand forecasting

- Supply planning

- Inventory optimization

- Advanced analytics

- Optimization of production scheduling taking into account labor, capacity constraints, sequencing rules, available materials

- Integration between demand and supply planning

- Integration with ERP

The project was challenging because of some business process and IT landscape specialties:

- Switch of users from legacy ERP system with site-specific views to new unified planning platform

- Seasonal shifts and changing consumer preferences difficult to forecast on daily level

- Ultra-fresh assortment leads to difficulties in serving customers while minimizing waste, stock should be managed in optimal way for 1500 SKUs across 10 DCs

- Planning of slow-moving products to avoid overstock and margin decrease due to discounting for getting rid of it

- Complex production process with switchovers for filling, cleaning, packaging large volumes of soups, pastas, sauces

- Production schedule should be optimized on detailed level to ensure needed throughput and efficient workforce allocation

Blount reduced forecast error by 50%, cut finished goods waste by over 35%, and improved production output by 5% — while maintaining its 20% CAGR.

Some useful links:

https://www.relexsolutions.com/resources/cpg-supply-chain-trends/

https://www.relexsolutions.com/customers/?industry=manufacturing-and-cpg

https://www.relexsolutions.com/resources/case-study-finsbury-food-group/

https://www.relexsolutions.com/resources/case-study-blount-fine-foods/

https://www.relexsolutions.com/resources/touchless-planning/Key takeaways

- The CPG industry presents significant challenges due to its high volumes and customer-centric operations, which demand a mature and agile approach to supply chain planning.

- Relex stands out as a leading vendor in supply chain planning for CPG companies, earning recognition from top research and advisory firms like Gartner.

- Its comprehensive solution portfolio — covering everything from demand forecasting to production scheduling — enables companies to boost service levels, reduce waste, and scale effectively.

- The case studies of Finsbury Food Group and Blount Fine Foods demonstrate how Relex solutions can help address complex planning challenges in real-world CPG environments.