4701

10 min

How to Achieve Ideal Warehouse KPIs with SAP EWM?

In today's competitive landscape, benchmarking is essential for businesses to gauge their performance against industry peers and identify areas for improvement. By analyzing key metrics, companies can gain valuable insights into their strengths and pinpoint opportunities to enhance operational efficiency.

For instance, while one warehouse takes 39 minutes to receive a truck, its competitors complete the same process in just 28-29 minutes. This stark difference reveals a potential for process optimization that could significantly boost efficiency.

In this article we’ll outline critical warehouse KPIs every business should monitor, explain how to calculate them, and demonstrate how implementing a Warehouse Management System (WMS) can help achieve these targets. From reducing operational costs to ensuring top-tier client service, we delve into the essential strategies for success.

Key Warehouse KPIs

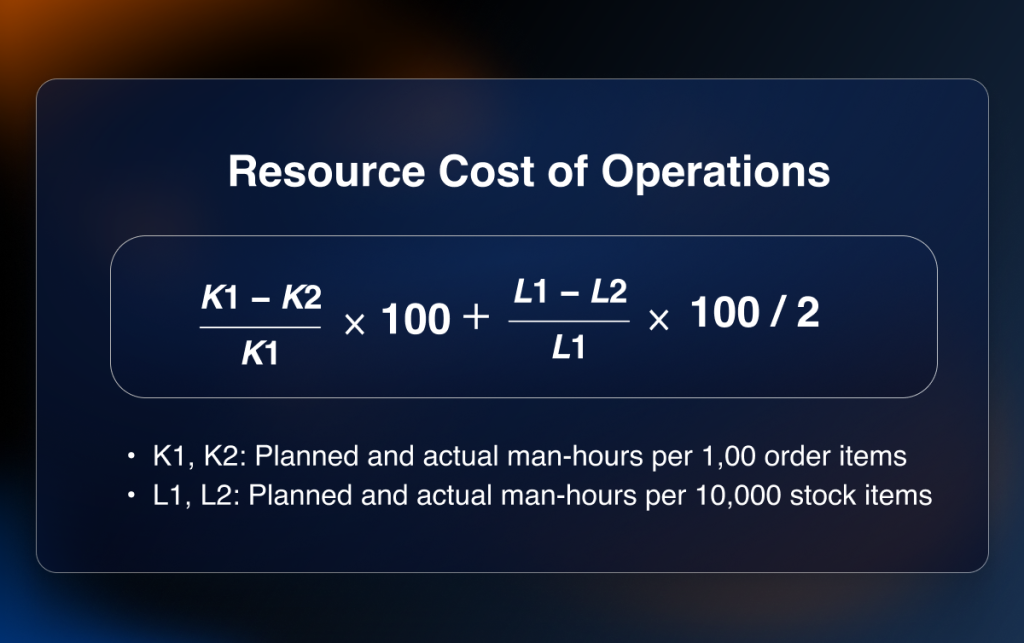

Resource Cost of Operations

This KPI evaluates the efficiency of warehouse operations in relation to resource costs. It measures the number of man-hours required for order processing, providing insights into how effectively labor resources are being utilized.Equals 100% if the warehouse has sufficient resources and technology to handle planned daily and seasonal workloads efficiently.

How to calculate?

Indexes:

K1, K2: Planned and actual man-hours per 1,000 order items

L1, L2: Planned and actual man-hours per 10,000 stock items

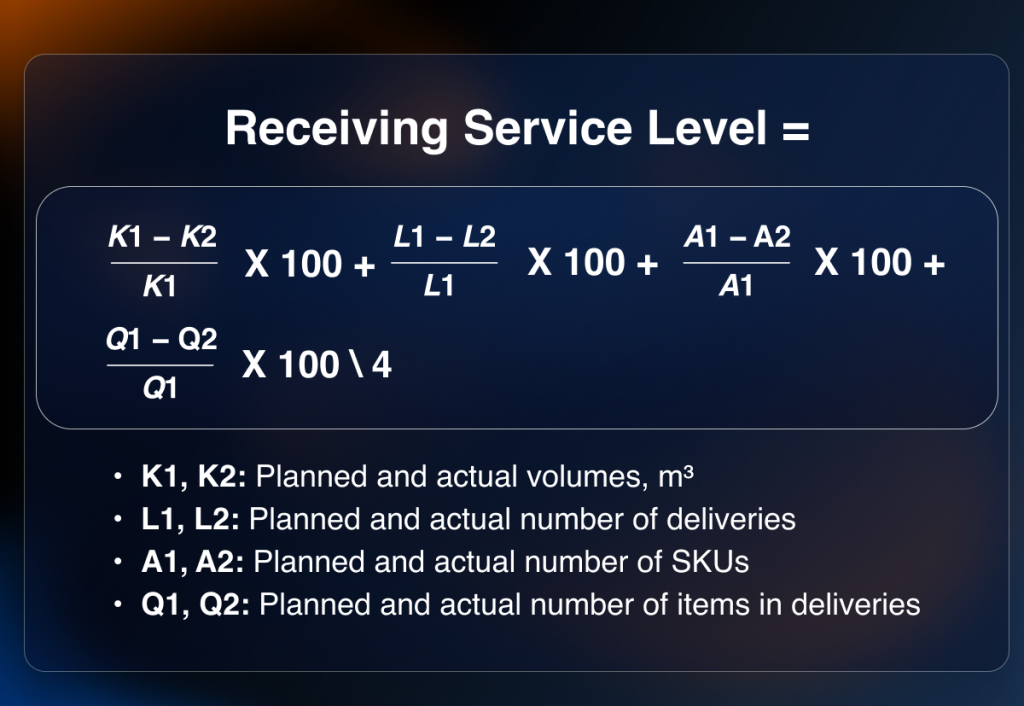

Receiving Service Level

This KPI measures how well the warehouse meets the requirements of the procurement department by comparing actual incoming volumes with planned volumes. It helps assess how promptly and accurately the warehouse performs receiving functions.

Equals 100% when the actual received volume matches the planned daily and seasonal deliveries.

How to calculate?

L1, L2: Planned and actual number of deliveries

A1, A2: Planned and actual number of SKUs

Q1, Q2: Planned and actual number of items in deliveries

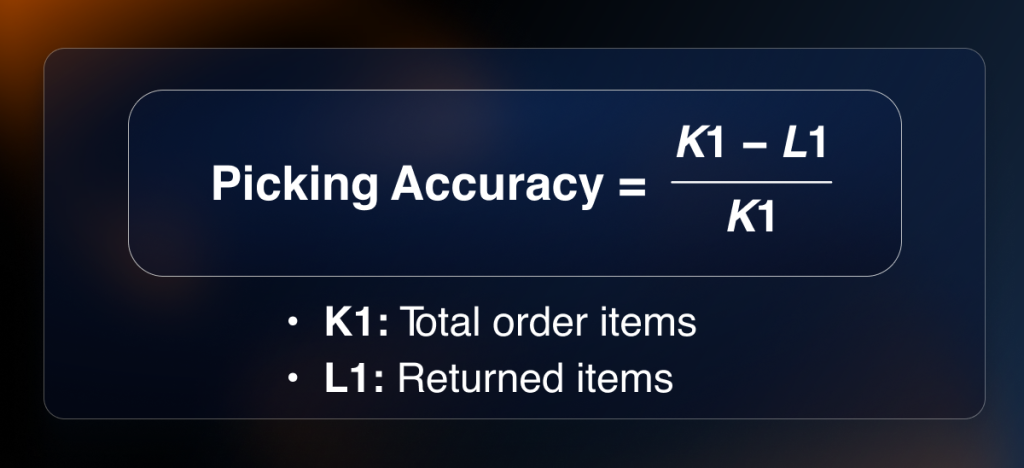

Picking Accuracy

Picking accuracy is a crucial measure of how precisely items are selected for customer orders. High accuracy not only improves overall warehouse efficiency but also enhances customer satisfaction by minimizing errors and reducing returns.

Aim for a picking accuracy close to 1, indicating minimal errors.

How to calculate?

K1: Total order items

L1: Returned items

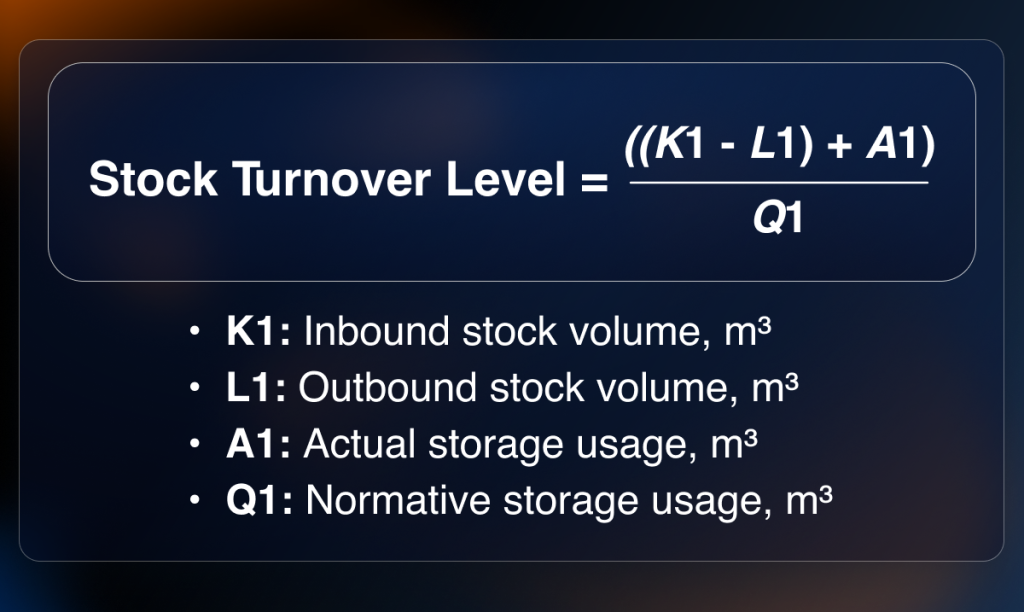

Stock Turnover Level

This indicator measures the volume of warehouse operations by analyzing the flow of incoming and outgoing goods relative to standard storage capacity. High turnover level signifies efficient space utilization and effective inventory management.

A turnover level close to or exceeding 1 indicates a high warehouse load.How to measure?

Indexes:

K1: Inbound stock volume, m³

L1: Outbound stock volume, m³

A1: Actual storage usage, m³

Q1: Normative storage usage, m³

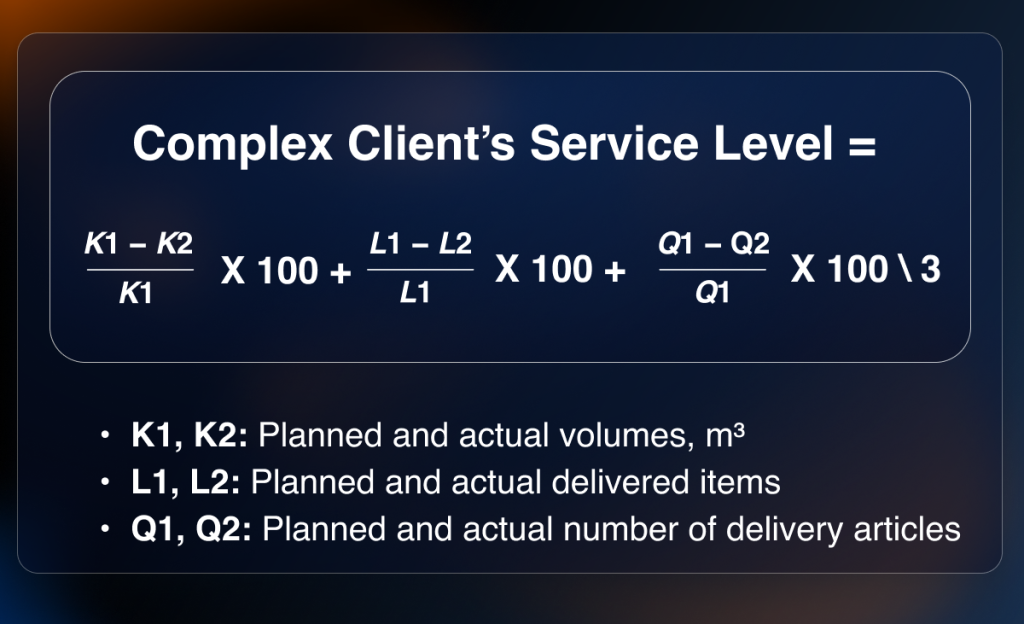

Complex Client Service Level

This KPI evaluates the warehouse’s ability to meet the sales department’s requirements by measuring the timeliness and accuracy of order fulfillment. It reflects the warehouse’s capability to satisfy client demands within set deadlines.This KPI equals 100% when the actual delivered volume meets the planned daily and seasonal deliveries.

How to measure?

Indexes:

K1, K2: Planned and actual volumes, m³

L1, L2: Planned and actual delivered items

Q1, Q2: Planned and actual delivered articles number

How to Improve KPIs Without Automation?

Resource Cost

To accelerate order processing without warehouse automation, you can consider hiring additional warehouse workers. However, this approach increases labor costs and may reduce efficiency if not properly managed. For instance, while more staff can speed up processing, it also drives up wages and logistical expenses.Receiving Service Level

Enhancing this metric involves improving supply planning and optimizing supplier interactions, albeit with increased administrative effort. Another option is to increase the number of workers involved in receiving, which can accelerate the processing of incoming goods.

Picking Accuracy

You can boost picking accuracy through staff training and implementing stringent quality control procedures, though these measures require significant time and financial investment. Introducing double checks at key stages of the picking process can also reduce errors.Stock Turnover Level

To enhance turnover, consider conducting more frequent inventories and optimizing warehouse layout schemes, even though this involves higher labor costs. Manual audits and recounts can quickly identify surpluses and shortages.Implementing the FIFO (First In, First Out) strategy can also help use goods with the earliest expiration dates first, minimizing losses and improving space utilization.

Complex Client Service Level

Improving this KPI may require additional control measures and enhanced coordination between departments, necessitating substantial management effort. Without automation, specialized teams can be created to handle urgent orders, improving customer service levels.Enhancing KPIs with SAP Extended Warehouse Management

Implementing Scanners (RF Guns)

The use of barcode scanners significantly reduces picking errors while speeding up order processing.For example, one of our projects saw a 10% productivity increase after implementing RF Gun technology. With 25 pickers and 11 forklift drivers, the savings amounted to 3.6 FTE (Full-Time Equivalent), equivalent to 164 man-hours annually.

Automating the picking process with SAP EWM ensures quick and accurate item retrieval, reducing errors and boosting productivity.

Workload Balancing and Leveling

Smart order picking strategies such as wave picking allow to minimize resource downtime, speed up order processing, balance workloads across shifts, and eliminate manual errors. Most importantly, they ensure that goods are always available in the picking area.Route Optimization and Resource Management

With a WMS solution like SAP EWM, you can optimize the internal warehouse movement routes, avoid empty runs, reduce logistics costs and increase order fulfillment speed. Real-time inventory management allows quick responses to demand fluctuations, preventing surpluses and shortages.Employee Motivation and Labor Management

Gamification systems can significantly boost employee productivity. In one of our projects, dashboards or simple LCD screens displayed current shift tasks, employee progress, productivity, and efficiency.These dashboards showed how many tasks needed to be completed during the shift and the progress made by a worker. Employees could see their productivity in real-time, receive visual cues like "tiger" or "turtle" and compare their progress with colleagues, fostering a competitive spirit.

Implementing such systems can increase productivity by 5-7%.

Monitoring and Analytics

SAP EWM offers powerful monitoring and analytics tools for warehouse operations. These tools allow managers to swiftly identify bottlenecks and make informed decisions to resolve them.For example, analytical reports can reveal the stages where picking errors occur most frequently, enabling targeted corrective actions and staff training.

Conclusion

Optimizing warehouse operations with a smart solution like SAP EWM can dramatically improve key performance indicators. By automating processes, integrating cutting-edge technologies, and effectively managing resources, your business can become more competitive and efficient.TeamIdea has 20-year practical experience in implementing such projects and we are ready to help your business achieve optimal warehouse KPIs.

If you’d like to evaluate the efficiency of your warehouse operations, contact us today to get a comprehensive Warehouse Assessment by TeamIdea.

Key takeaways

-

Why is benchmarking essential?

Benchmarking allows businesses to compare performance against industry peers, evaluate warehouse efficiency, and identify areas for improvement. -

What are the essential KPIs for warehouses?

Critical KPIs include resource cost, receiving service level, picking accuracy, stock turnover level, and complex client service level. -

How can you manually improve warehouse KPIs?

Manual improvement methods include hiring more workers, enhancing planning processes, and implementing quality control measures. -

What are the benefits of SAP EWM?

SAP EWM enhances KPIs through automation, real-time analytics, and optimized resource management.