5441

8 min

Inventory Management In Supply Chain Management in 2024

In the ever-evolving landscape of global commerce, Inventory Management has emerged as a cornerstone of Supply Chain Management (SCM). The fusion of cutting-edge technology and innovative strategies has transformed how businesses approach inventory control, ensuring efficiency and resilience in the face of fluctuating market demands.

This article delves into the latest advancements and methodologies that have redefined inventory management within SCM, highlighting the pivotal role of real-time data analytics, AI-driven forecasting models, and the integration of Internet of Things (IoT) devices. We will explore how these tools not only optimize stock levels but also enhance the agility of supply chains, enabling companies to navigate the complexities of today's economic environment with confidence and precision.

Join us as we unpack the nuances of modern inventory management and its critical impact on the success of supply chains in 2024.

Definition of Inventory Management in SCM

Inventory management in supply chain management (SCM) is the art and science of overseeing and controlling the ordering, storage, and utilization of inventory. This includes the management of raw materials, components, and finished products, as well as the warehousing and processing.

The goal of inventory management is to maintain optimal inventory levels, ensuring that products are available to meet customer demand without overstocking or understocking. Key activities involve tracking inventory levels, orders, sales, and deliveries, all aimed at maintaining optimal inventory levels.

Why is Inventory Management Crucial for Supply Chain Efficiency?

Efficient inventory management is the backbone of a successful supply chain. It ensures that there is a balance between supply and demand, reducing the risk of stockouts and excess inventory.

This not only enhances customer satisfaction by ensuring timely product availability but also minimizes costs connected with holding and managing inventory. Furthermore, good inventory management practices improve cash flow and operational efficiency. By implementing inventory control best practices, businesses can optimize their supply chain inventory control processes, leading to enhanced overall performance.

The goal of this guide

In this guide we will provide a complete overview of inventory management in SCM.

We'll dive into the basics, explore various inventory control techniques, discuss the role of technology and tools, address common challenges, and offer strategies for effective management.

In addition, we'll look at real-world cases and future trends to help businesses optimize their inventory practices and achieve supply chain excellence.

Fundamentals of Inventory Management

Overview of Inventory Within the Supply Chain

Inventory is a critical component of the supply chain, encompassing all the goods, materials, and products that a company holds for the purpose of resale, production, or utilization in services.

The inventory management process involves careful tracking and control of these items to ensure their availability when needed while minimizing costs. Inventory and distribution management play a pivotal role in ensuring that the right products are delivered to the right place at the right time.

Effective inventory management in the supply chain helps to balance the costs of holding inventory against the need to meet customer demand.

Objectives of Inventory Management

The primary objectives of inventory management include:

- Ensuring product availability to meet customer demand.

- Minimizing the costs connected with ordering, holding, and managing inventory.

- Optimizing inventory turnover to reduce the risk of obsolescence and spoilage.

- Enhancing supply chain efficiency and responsiveness.

- Improving cash flow by reducing excess inventory and freeing up capital.

These objectives are achieved through the implementation of various inventory management strategies and inventory control procedures, which help to streamline the inventory process and improve overall supply chain performance.

Types of Inventory

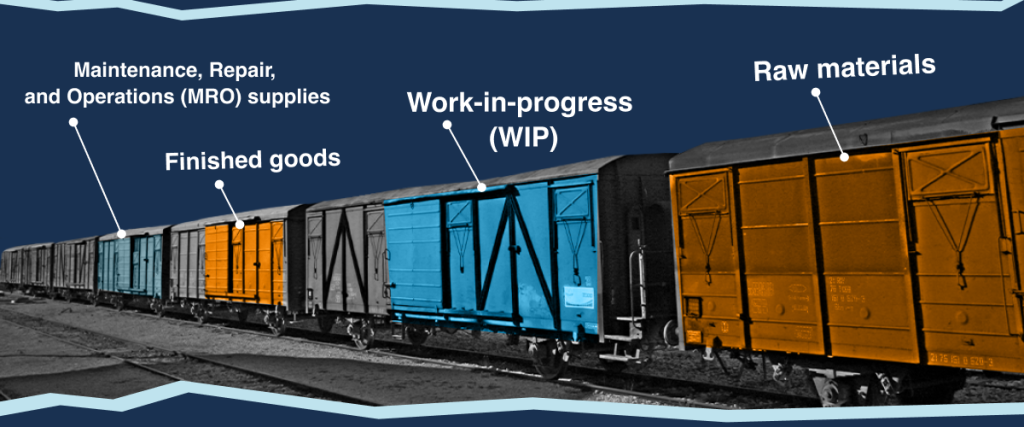

Inventory can be categorized into several types based on its stage in the supply chain and its purpose. These include:

- Raw materials: Basic materials used in the production of goods.

- Work-in-progress (WIP): Items that are in the process of being manufactured.

- Finished goods: Completed products ready for sale or distribution.

- Maintenance, Repair, and Operations (MRO) supplies: Items used in the production process but not part of the final product.

Understanding the different types of inventory is essential for implementing effective inventory management practices and ensuring efficient supply chain operations.

Inventory Costs and Impact on Supply Chain Performance

Inventory costs can be broadly classified into ordering costs, holding costs, and shortage costs.

Ordering costs are incurred during the procurement of inventory, while holding costs include storage, insurance, and obsolescence costs.

Shortage costs arise when inventory levels are insufficient to meet demand, leading to lost sales and customer dissatisfaction. These costs have a significant impact on supply chain performance, and effective inventory management techniques aim to balance these costs to optimize overall efficiency.

Implementing inventory control procedures and good inventory management practices helps in reducing these costs and improving supply chain performance.

Inventory Control Techniques

Economic Order Quantity (EOQ) Model

The Economic Order Quantity (EOQ) model is a fundamental inventory management technique used to determine the optimal order quantity that minimizes total inventory costs.

This model balances ordering costs with holding costs to find the most cost-effective order quantity. The EOQ formula is used to calculate the ideal order size that minimizes the total cost of inventory, including both ordering and holding costs.

By implementing the EOQ model, businesses can reduce excess inventory, lower holding costs, and improve their inventory management workflow.

Just-In-Time (JIT) Inventory Management

Just-In-Time (JIT) inventory management is a strategy that aims to reduce inventory levels by aligning orders with production schedules.

The goal of JIT is to minimize holding costs and reduce waste by receiving goods only when they are needed for production or sales.

This approach requires precise demand forecasting and strong supplier relationships to ensure timely deliveries.

JIT inventory management helps businesses improve their cash flow, reduce storage costs, and enhance overall supply chain efficiency.

ABC Analysis for Inventory Classification

ABC analysis is an inventory classification technique that categorizes inventory items into three groups based on their importance and value.

- Category A: High-value items with a significant impact on overall inventory costs.

- Category B: Moderate-value items that require regular monitoring and control.

- Category C: Low-value items that are less critical to overall inventory management.

By prioritizing inventory management efforts based on the ABC classification, businesses can focus their resources on managing the most critical items, improving inventory control and optimizing supply chain performance.

Vendor-Managed Inventory (VMI) Systems

Vendor-Managed Inventory (VMI) systems involve suppliers managing the inventory levels of their products at the buyer's location.

This collaborative approach enhances supply chain efficiency by reducing the buyer's responsibility for inventory management and ensuring that inventory levels are optimized based on real-time demand data. VMI systems improve inventory accuracy, reduce stockouts, and enhance supplier-buyer relationships. By leveraging VMI systems, businesses can achieve better inventory control and streamline their inventory management process.

Safety Stock and Reorder Point Determination

Safety stock is the extra inventory held to prevent stockouts due to demand variability or supply chain disruptions. Determining the appropriate safety stock level involves analyzing demand patterns and variability, as well as lead times. The reorder point is the inventory level at which a new order should be placed to replenish stock before it runs out.

Calculating the reorder point involves considering the lead time and average demand during that period. Implementing safety stock and reorder point determination techniques helps businesses maintain a smooth inventory flow, prevent stockouts, and ensure continuous operations.

Technology and Tools for Inventory Management

Inventory Management Software Systems

Inventory management software systems automate the inventory control procedures, providing real-time data and analytics to help businesses make informed decisions. These systems offer features such as inventory tracking, order management, demand forecasting, and reporting.

By using inventory management software, businesses can streamline their inventory management workflow, reduce manual errors, and enhance overall efficiency. An effective inventory management system definition includes the ability to integrate with other business systems, such as ERP and SCM software, to provide a comprehensive solution for managing inventory.

RFID and Barcode Technology for Inventory Tracking

RFID (Radio Frequency Identification) and barcode technology enable precise tracking of inventory items throughout the supply chain. These technologies improve inventory accuracy, reduce manual errors, and enhance inventory visibility. RFID tags and barcode labels are attached to inventory items, allowing for real-time tracking and automated data capture.

By implementing RFID and barcode technology, businesses can improve their inventory control best practices, streamline their inventory management process, and enhance overall supply chain efficiency.

IoT Devices and Sensors for Real-Time Inventory Monitoring

Internet of Things (IoT) devices and sensors provide real-time data on inventory levels, helping businesses monitor and manage their inventory more effectively. These devices can track the location, condition, and status of inventory items, providing valuable insights into inventory levels and movement.

IoT devices and sensors are particularly useful for tracking perishable goods, ensuring timely replenishment, and preventing spoilage. By leveraging IoT technology, businesses can enhance their inventory management functions, improve inventory accuracy, and optimize their supply chain operations.

Data Analytics

Data analytics plays a crucial role in inventory management by providing insights into demand patterns, inventory levels, and supply chain performance. By analyzing historical data and using predictive analytics, businesses can improve their demand forecasting, optimize inventory levels, and make data-driven decisions.

Data analytics helps businesses identify trends, detect anomalies, and uncover opportunities for improvement. Implementing data analytics in inventory management enables businesses to enhance their inventory control procedures, improve overall efficiency, and achieve better supply chain performance.

Challenges in Inventory Management

Bullwhip Effect and Supply Chain Variability

The bullwhip effect refers to the amplification of demand variability as it moves up the supply chain. Small fluctuations in customer demand can lead to larger variations in orders placed with suppliers, causing inefficiencies and increased costs. The bullwhip effect can result in excess inventory, stockouts, and reduced supply chain performance.

Effective inventory management techniques, such as accurate demand forecasting and improved communication between supply chain partners, can help mitigate the bullwhip effect and reduce supply chain variability.

Demand Forecasting Inaccuracies

Inaccurate demand forecasting can lead to significant inventory management challenges, including stockouts and overstocking. Demand forecasting inaccuracies arise from factors such as changing customer preferences, market trends, and external disruptions.

To improve demand forecasting accuracy, businesses can use advanced forecasting techniques, data analytics, and collaborative planning with supply chain partners. Accurate demand forecasting is essential for maintaining optimal inventory levels and ensuring efficient supply chain operations.

Stockouts and Overstocking

Stockouts occur when inventory levels are insufficient to meet customer demand, leading to lost sales and customer dissatisfaction. Overstocking, on the other hand, results in excess inventory that ties up capital and incurs holding costs.

Both situations highlight the importance of precise inventory control and effective inventory management practices. By implementing inventory control best practices, businesses can balance inventory levels, reduce the risk of stockouts and overstocking, and optimize supply chain performance.

Inventory Obsolescence and Spoilage

Inventory obsolescence and spoilage occur when products become outdated or deteriorate over time. This challenge is particularly relevant for businesses dealing with perishable goods or products with a short lifecycle.

Effective inventory management techniques, such as regular inventory reviews, demand forecasting, and proper storage practices, can help reduce the risk of obsolescence and spoilage. By addressing these challenges, businesses can minimize losses, improve inventory turnover, and enhance overall supply chain efficiency.

Inventory Shrinkage and Theft

Inventory shrinkage and theft are significant concerns for businesses, leading to financial losses and reduced inventory accuracy. Shrinkage can result from various factors, including employee theft, shoplifting, administrative errors, and supplier fraud.

Implementing robust inventory control procedures, such as regular audits, security measures, and employee training, can help mitigate the risk of shrinkage and theft. By addressing these challenges, businesses can improve their inventory accuracy, reduce losses, and enhance overall supply chain performance.

Strategies for Effective Inventory Management

Collaborative Planning, Forecasting, and Replenishment (CPFR)

Collaborative Planning, Forecasting, and Replenishment (CPFR) is a strategy that involves supply chain partners working together to improve demand forecasting and inventory replenishment. CPFR enhances supply chain coordination by sharing information, aligning forecasts, and jointly managing inventory levels. This collaborative approach helps reduce the bullwhip effect, improve demand accuracy, and optimize inventory levels. Implementing CPFR can lead to better inventory management practices and enhanced overall supply chain efficiency.

Cross-Functional Alignment Between Inventory and Other SCM Functions

Aligning inventory management with other supply chain management (SCM) functions, such as procurement, production, and distribution, ensures a cohesive approach to supply chain operations.

Cross-functional alignment helps in optimizing inventory levels, improving demand forecasting, and enhancing overall supply chain performance. By fostering collaboration between different SCM functions, businesses can streamline their inventory management process, reduce costs, and achieve better operational efficiency.

Lean Principles for Waste Reduction and Efficiency Improvement

Lean principles focus on eliminating waste and improving efficiency in inventory management. Lean inventory management techniques aim to reduce excess inventory, minimize holding costs, and enhance overall supply chain performance.

By adopting lean practices, businesses can streamline their inventory processes, improve inventory turnover, and reduce lead times. Implementing lean principles helps in achieving good inventory management practices and optimizing supply chain operations.

Continuous Improvement Through Performance Metrics and KPIs

Implementing performance metrics and key performance indicators (KPIs) allows businesses to monitor their inventory management process and identify areas for improvement. Continuous improvement efforts involve regularly reviewing and analyzing performance data, setting targets, and implementing corrective actions. By using performance metrics and KPIs, businesses can enhance their inventory control procedures, improve overall efficiency, and achieve better supply chain performance. Continuous improvement is essential for maintaining optimal inventory levels and ensuring long-term success in inventory management.

Case Studies and Examples

Examining real-world examples and case studies of successful inventory management projects provides valuable insights into best practices and effective strategies. These examples illustrate how businesses have overcome inventory management challenges and achieved supply chain excellence. By analyzing these case studies, businesses can learn from the experiences of others and apply proven inventory management techniques to their own operations. Understanding how to do inventory effectively through real-world examples helps businesses implement step-by-step inventory processes and achieve better results.

High-tech discrete manufacturing case study

Challenges:

- Surplus inventories for Maintenance, Repair and Overhaul (MRO)

- Unaccounted for stocks of workshops

- The need for frequent regular maintenance of mills and presses with oil change and impossibility to carry out partial write-off of 10 litres from a 250 litre drum.

- Difficulties in preparation of audit reports, distorted picture of expenditures on MRO

Solutions:

- Implementation of MRO planning in the context of orders

- Implementation of material accounting in the context of workshop warehouses

- Amnesty period for masters' co-operation in detecting unaccounted for materials

- Reflection of material write-offs by litre for a specific MRO order

Result:

- Transparency and correctness of the inventory and cost picture for auditing.

- Reduced material costs for MRO due to more efficient allocation of stock between workshops.

Inventory Planning transformation for a Car Seats Producer (based on SAP IBP)

Project: Digital transformation for inventory planning based on SAP IBP for Inventory

Client: Leading car seats producer with 500+ mln $ revenue operating in EU, MENA regions

Timeline: Q3 2023–Q1 2024 (6 months)

Organizational scope: 4 plants (2 in EU, 2 in MENA region). All components and raw materials

Project features:

- Moving from 2 week horizon to 6-9 months horizon in stock planning using advanced techniques such as multistage stock optimization for calculation of safety stock, target inventory position calculation. Stock reporting and analytics: 2 dashboards with 12 analytical charts including stock value metrics coming from SAP Best practice.

- Building SAP IBP center of excellence in Customer team, key users trainings for SAP IBP for Inventory, IT trainings for CI-DS. At the end of the project Customer center of excellence consisted of 1 CI-DS expert and 3 IBP experts (build from team with little IBP experience).

- Proving support for Customer-led development for integrating SAP S/4 HANA with SAP IBP.

- Adding extra fields and custom field mapping logic on SAP IBP and CI-DS side for covering user requirements and automotive specifics (such as JIT and JIS production processes for finish goods, phantom materials, subcontracting, flow-through delivery, customer forecast provided via EDI).

- Performing business validation sessions for high quality FIT/GAP analysis and providing ways of resolution with estimation for each GAP.

Result:

- 4 plants started using SAP IBP

- 4 сustomer employees got involved in IBP сenter of Excellence

- x2 planning horizon extended

- +12 new stock analyticscharts

Future Trends and Innovations in Inventory Management

The future of inventory management is shaped by emerging trends and innovations that promise to enhance efficiency and accuracy. Technologies such as artificial intelligence (AI), machine learning, and blockchain are expected to revolutionize the inventory management process. AI and machine learning can improve demand forecasting, optimize inventory levels, and automate routine tasks.

Blockchain technology provides greater transparency and traceability in the supply chain, enhancing inventory accuracy and security. These innovations, along with advancements in IoT and data analytics, will enable businesses to achieve better inventory control and enhance overall supply chain performance.

Conclusion

In conclusion, effective inventory management is essential for the success of any supply chain. By understanding the fundamentals, adopting advanced techniques and technologies, addressing challenges, and implementing best practices, businesses can optimize their inventory management process and achieve supply chain excellence.

Embracing future trends and innovations will further enhance the capabilities of inventory management, ensuring that businesses remain competitive in a dynamic market environment. Through continuous improvement and the application of proven strategies, businesses can achieve optimal inventory levels, reduce costs, and improve overall supply chain efficiency.

Key takeaways

-

Inventory management in SCM

Inventory management in SCM involves overseeing and controlling the ordering, storage, and utilization of inventory to ensure optimal levels, minimize costs, and meet customer demand efficiently using advanced technologies and strategies. -

Why is inventory management important for businesses?

It ensures a balance between supply and demand, reducing the risks of stockouts and excess inventory. This optimization enhances customer satisfaction through timely product availability, and improves cash flow and overall operational efficiency. -

What are some common inventory management techniques?

Common techniques include Economic Order Quantity (EOQ), Just-In-Time (JIT), ABC analysis, Vendor-Managed Inventory (VMI), maintaining safety stock, and determining reorder points. -

How do technology and tools improve inventory management?

Technologies such as inventory management software, RFID, barcode systems, IoT devices, and data analytics enhance inventory accuracy, visibility, tracking, and decision-making, leading to more efficient and effective inventory management practices. -

What challenges are commonly faced in inventory management?

Common challenges include the bullwhip effect, inaccurate demand forecasting, stockouts, overstocking, inventory obsolescence and spoilage, and shrinkage due to theft or errors.