3974

10 min

Reducing Spoilage in the FMCG Industry: Key Strategies for Fresh and Ultra-Fresh Products

Spoilage is a real headache for the FMCG sector companies, particularly as the demand for fresh, natural products continues to rise. Picture the effort put into ensuring the best quality, only to face the disappointment of products spoiling before they even reach consumers.

This article delves into the challenges of managing spoilage in FMCG, particularly focusing on perishables and ultra-fresh products, and explores practical solutions for minimizing expiry write-offswaste and improving margins. Discover how to tackle spoilage head-on and transform a problem into an opportunity for efficiency.

The challenge of wasted food reducing goods spoilage in FMCG

FMCG companies heavily rely on retail chains as their primary clients. They are, in turn, cater to end consumers whose preferences have increasingly shifted towards local, natural, and healthy food options.

This trend has driven a demand for fresh dairy, fruits, vegetables, pastries, meat, and fish. Consumers often perceive packaged and preserved products as less healthy because they believe that healthy food should be fresh and natural.

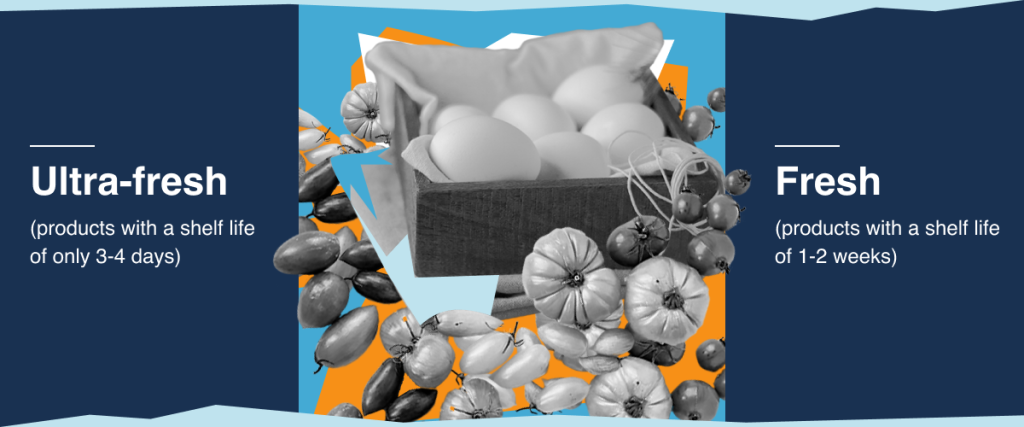

Perishables can be split into two categories:

- Ultra-fresh perishables: Products with a shelf life of only 3-4 days.

- Fresh perishables: Products with a shelf life of 1-2 weeks.

Unlike items with a long shelf life, FMCG products must be delivered and sold quickly to avoid expiry wastage, leading to financial losses for both manufacturers and retailers. The remaining shelf-life when product arrives at the store should meet retailer’s minimum limitations. Overwise retailers are obliged to do sales-outs leading to reduction of their margin. This hits on retailer-manufacturer relationships since retailers always choose the most profitable way of supply.

Strategies to minimize spoilage

Accurate forecasting

FMCG companies need to implement forecasting algorithms tailored specially for perishables. These algorithms should operate on a daily level, incorporating demand-sensing techniques to adapt quickly to the latest trends. It’s crucial to run forecast for perishables on a daily basis having latest sales data, so it should be automated.

Additionally, forecasts must account for promotions and price reductions, as errors in predicting the impact of promotions can lead to overstocking and subsequent spoilage. With a big number of SKUs this process should be automated to get precise uplift effect evaluation.

Flexible and responsive production planning

Accurate forecasting alone is not enough; production must be flexible to align with the sensed demand. This requires tight integration between forecasting and production planning systems and possibility to recalculate production plan on the fly in case of forecast changes.

Minimizing the freeze horizon in production planning allows for greater responsiveness to demand fluctuations, reducing the risk of overproduction and spoilage.

Minimum acceptable shelf life planning

FMCG companies must plan the minimum acceptable remaining shelf life when shipping products from distribution centers (DCs) to stores. Each retail chain has specific requirements for shelf life, and failing to meet them can result in product refusals and penaltieslosses.

Knowing and following the remaining shelf life requirements of different retailers helps prevent products from being rejected. This planning is important for keeping good relationships with retailers and reducing expiry write-offswaste.

The Role of Technology in Perishables stock management

Technological solutions, such as SAP IBP and SAP EWM, SAP TM, play a crucial role in improving spoilage management. These systems offer advanced features for forecasting, production planning, transportation management, and batch management, all of which contribute to reducing spoilage and increasing efficiency.

Transportation Management: Ensures that perishables are transported with the fastest route and under optimal conditions to preserve their quality and extend remaining shelf life.

Batch Management: Allows for precise stock management by tracking the remaining shelf life of different batches, ensuring that products are used in the right order to minimize spoilage (FIFO - first in, first out).

Case studies: successful projects by TeamIdea

Major FMCG holding

A large FMCG brand that produces dairy and meat products faced challenges in forecasting and planning outbound deliveries for perishables. They lacked automated tools and relied on manual predictions in Excel, which led to high spoilage rates.

What we implemented:

- Enhanced forecasting at a detailed level (SKU-, client-, and week).

- Configured demand-influencing factors like promotions using advanced techniques such as gradient boosting and multi-linear regression.

- Recovered baseline sales history on daily level to improve forecast accuracy.

- Highly detailedDisaggregated planning of outbound deliveries onto location-, day-, and SKU levels.

- Calculated minimum acceptable remaining shelf life for outbound deliveries.

Results:

- Improved forecast accuracy to 75%, significantly reducing manual work and improving outbound delivery planning.

- Improved understanding of remaining shelf life requirements, reducing product refusals and spoilage rates.

Leading poultry producer

The company needed to maximize the margin by selling more fresh meat, as fresh products typically command higher prices and subsequently higher margin than frozen ones.

What we implemented:

- Configured industry-specific optimization algorithms for production planning, considering weight, size, and shelf life limitations.

- Implemented margin planning with profit and loss accounting and “what if” scenario modeling.

- Elevated decision-making on production, cutting options, and freezing proportions to maximize margins meeting short-term customer demands.

Results:

- The company achieved a 2% increase in margin across its operations, highlighting the substantial financial benefits of improved planning and optimization.

Conclusion

While some amount of spoilage in the FMCG industry is inevitable due to the perishable nature of fresh and ultra-fresh products, effective planning can significantly reduce expiry write-offswaste.

Implementing accurate forecasting, flexible production planning, and stringent shelf life management are key strategies that FMCG companies can adopt to improve efficiency and profitability.

Key takeaways

-

How can accurate forecasting help?

Automated forecasting algorithms on a daily basis helps avoid overproduction and reduces product spoilage. -

Why is flexible production planning important?

Integrating forecasting and production planning allows for quick responses to demand changes, minimizing spoilage risks. -

What is the role of minimum shelf life management?

Planning shipments with minimum remaining shelf life requirements helps prevent product rejections and reduces losses. -

How does technology improve stock management?

Implementing technological solutions like SAP IBP and SAP EWM enhances spoilage management through optimized transportation and batch control. -

What do successful case studies present?

Advanced forecasting and planning methods significantly reduced spoilage and increased product margins for major FMCG companies.