5973

7 min

Sales and Operations Planning in FMCG: Common Challenges and How to Deal with Them

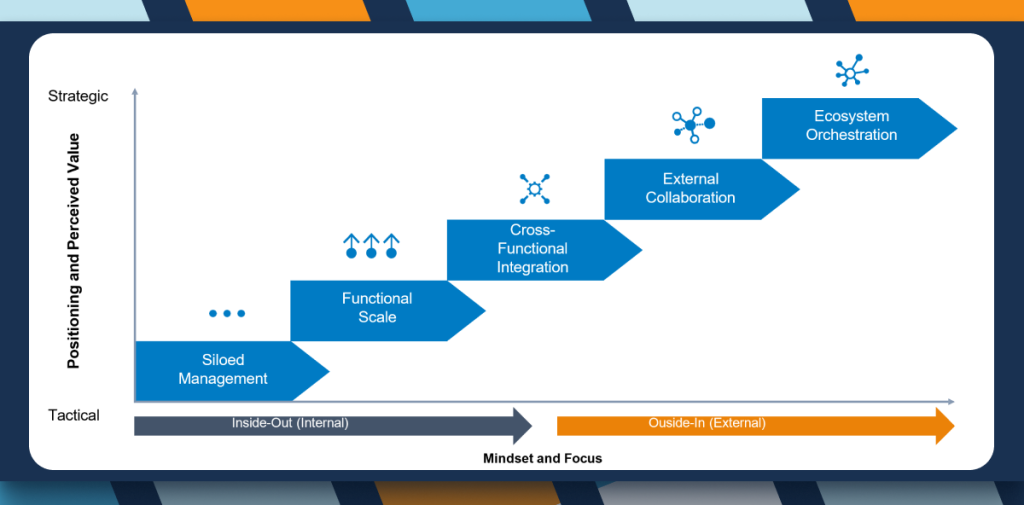

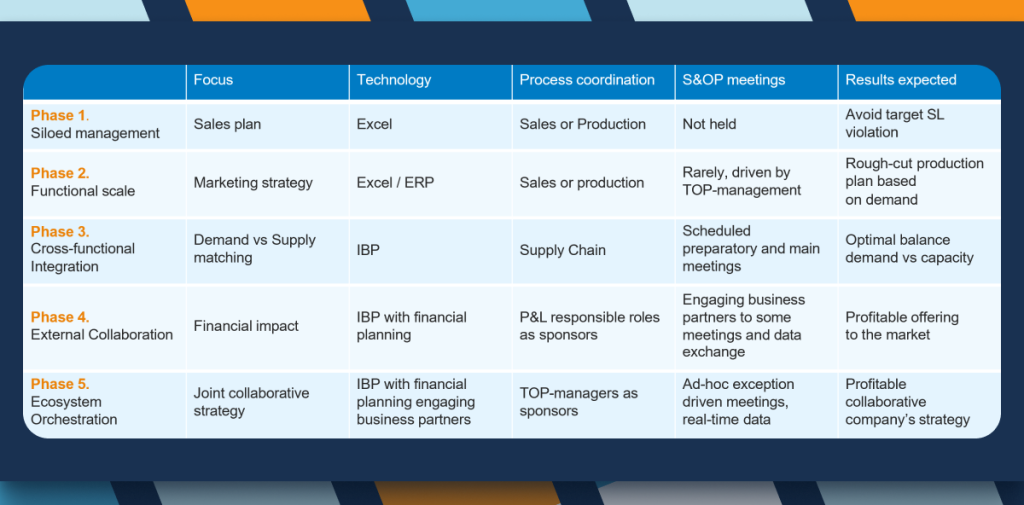

The stages of S&OP maturity

Gartner categorizes S&OP processes in the companies into five maturity levels, each representing a different phase of integration.

- Siloed management

- Functional scale

- Cross-functional integration

- External collaboration

- Ecosystem orchestration

Why do you need to collaborate with business partners? Case Study

Let's consider a real-world example from our practice involving a major International Preserved and Frozen Vegetables Producer. This company operates 3 factories in the CIS and produces up to 95,000 tonnes of canned vegetables annually.Before setting up the S&OP process, the Commerce Department was responsible for building the demand plan, which they primarily based on their expert market feeling.

Concurrently, the Procurement Department initiated a significant contract to distribute imported frozen vegetables, anticipating a substantial demand. But there was a communication gap. The Commerce Department had overestimated the potential market demand without consulting with major clients, the top retail chains. They also failed to discuss potential risks with the Client Service Department, which maintained close relationships with these retail chains.

As a result, the retail chains began selling the same frozen vegetables under their own brand at a lower price. The market dynamics shifted dramatically. The Commerce Department's miscalculation became evident as the expected demand did not materialize.

This overestimation of demand resulted in significant overstock. With the looming risk of product expiration, the company was forced into a situation of forced sales, often at discounted rates. Furthermore, the fixed volumes of the purchasing contract with the suppliers could not be adjusted, leading to substantial revenue and profit losses.

This case highlights the critical importance of inter-departmental communication and market intelligence in demand planning. By failing to coordinate with key business partners, the company faced avoidable financial setbacks.

Effective communication and a collaborative approach to demand planning with retail chains could have mitigated these risks and aligned production with actual market demand.

Another recommendation here is to evaluate departmental initiatives for risks during S&OP meetings with other departments, particularly the client service department and key account managers and incorporate these risks into the development of contract terms (contract volumes could be more flexible in our case).

Common mistakes during the S&OP implementation

Conflicting KPIs

Common mistake involves conflicting key performance indicators between departments. For instance, the supply chain department may aim to reduce stock levels, while the sales department wants to increase stock to improve service levels. Without a unified strategy, these conflicting objectives can hinder the overall S&OP process.

Lack of process owner

The absence of a clear S&OP process owner can lead to delays in decision-making. For example, in one of our cases with a poultry production company, we faced this issue: despite having an S&OP process in place, the lack of a dedicated owner resulted in prolonged decision-making times and inefficiencies.

Implementation without automation and careful meetings preparation

A major poultry producer faced challenges in planning and approving logistics costs, including sea route planning for exports. The logistics department applied the same detailed calculation expectations for long-term (1 year) and short-term planning. This required complex disaggregation calculations at the SKU level, managed with expert-defined, time-dependent weight coefficients. The routine manual work led to high overtime and eventually the dismissal of analysts. Frequent changes in transportation prices and conditions made detailed long-term plans quickly imprecise, reducing the benefit of the detailed long-term plans done manually.

Tips for successful S&OP transformation

To ensure a successful implementation of the S&OP, we recommend a balanced approach focusing on both people and technology. Key tips include:

- Have a top management sponsor (like a CEO or CFO) to ensure the S&OP process aligns with overall business goals.

- Identify and promote employees who drive innovation and believe in the S&OP process to foster collaboration and continuous improvement.

- Establish clear documentation and measurable targets for the S&OP process to avoid conflicts and ensure all departments work together towards common goals.

- Leveragе mobile-friendly IT solutions that allow for real-time plan adjustments. It can significantly reduce preparation lead time and improve decision-making efficiency. Use systems that can calculate the financial impact of different scenarios to choose the most profitable options.

Effective S&OP in the FMCG sector requires a combination of strategic collaboration, clear ownership, and robust IT support. By following best practices and addressing common pitfalls, companies can enhance their planning processes, leading to better alignment, improved efficiency, and increased profitability.

Get advice tailored to your specific project needs from our planning experts and SCM architects. Book a business discovery meeting with TeamIdea.

Key takeaways

-

What is the significance of S&OP in the FMCG industry?

Effective Sales and Operations Planning (S&OP) is crucial in the fast-paced FMCG industry to address rapid changes in customer preferences and stay competitive. -

What are the stages of S&OP maturity?

S&OP maturity levels range from basic “Siloed management” to advanced “Ecosystem orchestration” each representing different levels of integration and data exchange. -

Why is understanding S&OP maturity stages important?

It helps companies progress through stages, improving planning accuracy and operational efficiency. -

What common mistakes do businesses face in S&OP implementation?

Issues include using diverse systems, conflicting KPIs between departments, and the absence of a dedicated S&OP process owner, leading to inefficiencies and decision-making delays. -

What are the key tips for successful S&OP transformation?

Having a top management support, promoting innovation, establishing clear documentation and measurable targets, and leveraging mobile-friendly IT solutions for real-time adjustments.