Supply Chain Planning (based on SAP IBP)

Supply Chain Planning (based on SAP IBP)

Contact UsIs your business operating in a highly competitive market where product life cycles are short, demand is volatile, and supply chain complexities are significant?

Are you looking for ways to respond to customer demand more effectively, improve supply chain visibility and achieve sustainable growth?

Then answer a few more questions.

Is your planning still manual and spreadsheet-based? Conducted in siloed systems, with key Departments having their own, disconnected plans?

To stand the competition in Industry 4.0, you need to make a step forward. You need to win the most important resource. Time. And the path to success starts with a connected, precise plan.

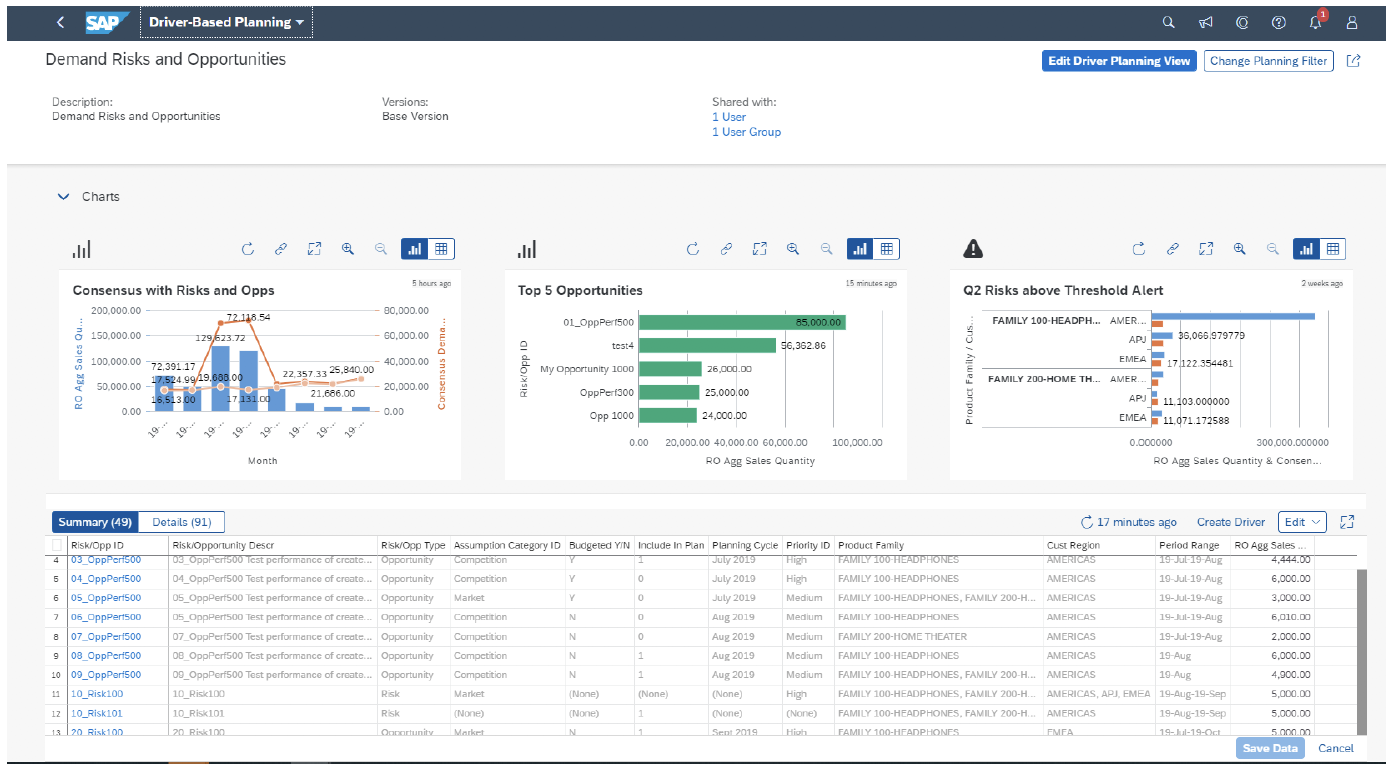

Meet SAP Integrated Business Planning! Cloud-based application, designed to enhance and streamline planning processes across various business functions like Sales, Finance, Inventory, Demand, and Supply.

Integrated, AI-empowered, and collaborative solution, enabling businesses to improve agility, responsiveness, and decision-making effectiveness across the supply chain. As a result – more efficiency, less human errors, and freed up time for strategic analysis and decision-making!

-

1.

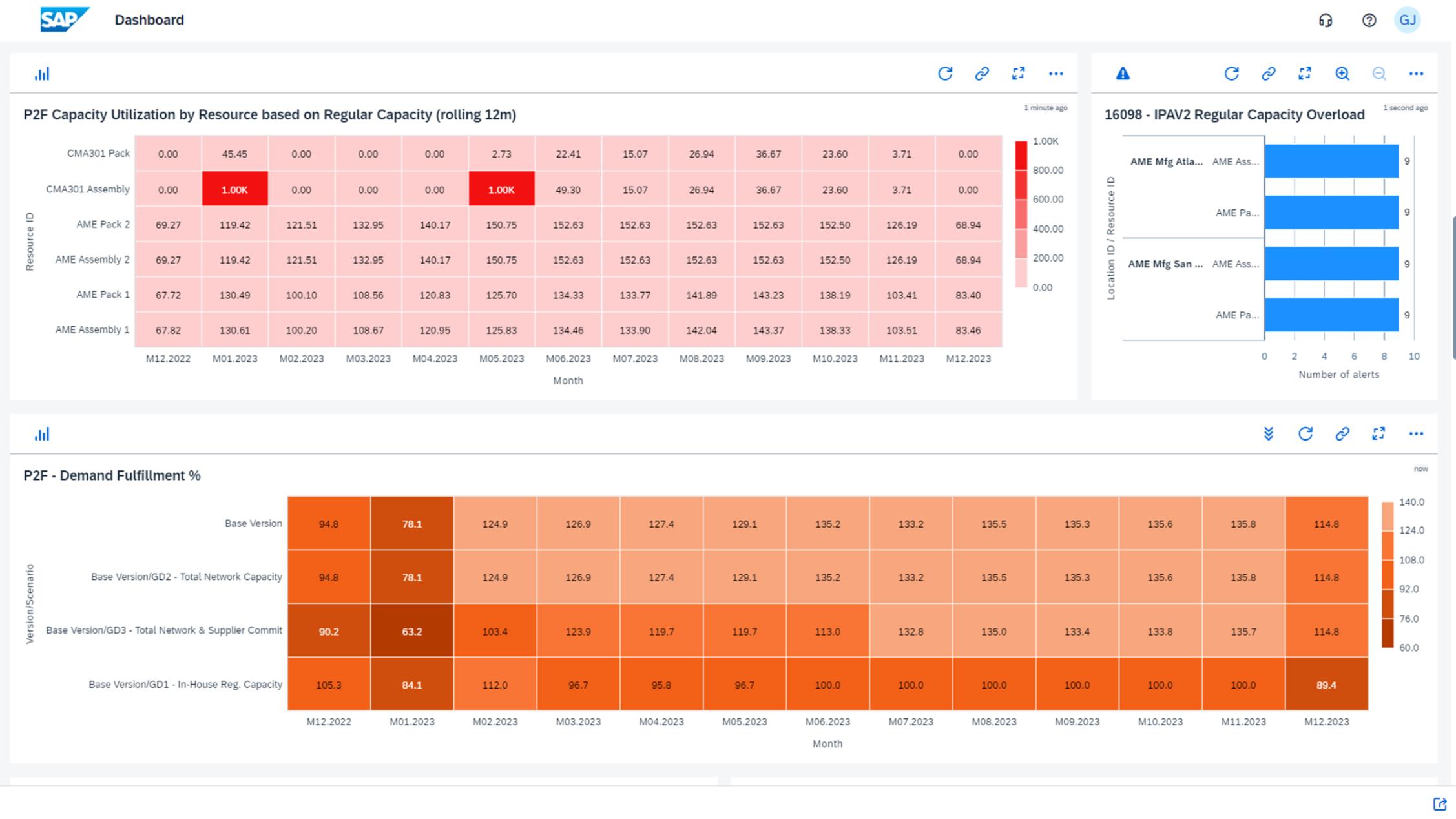

Leverage historical sales data, market trends, and promotional activities to create accurate demand forecasts at various levels of granularity (product families, regions, and customer segments).

-

2.

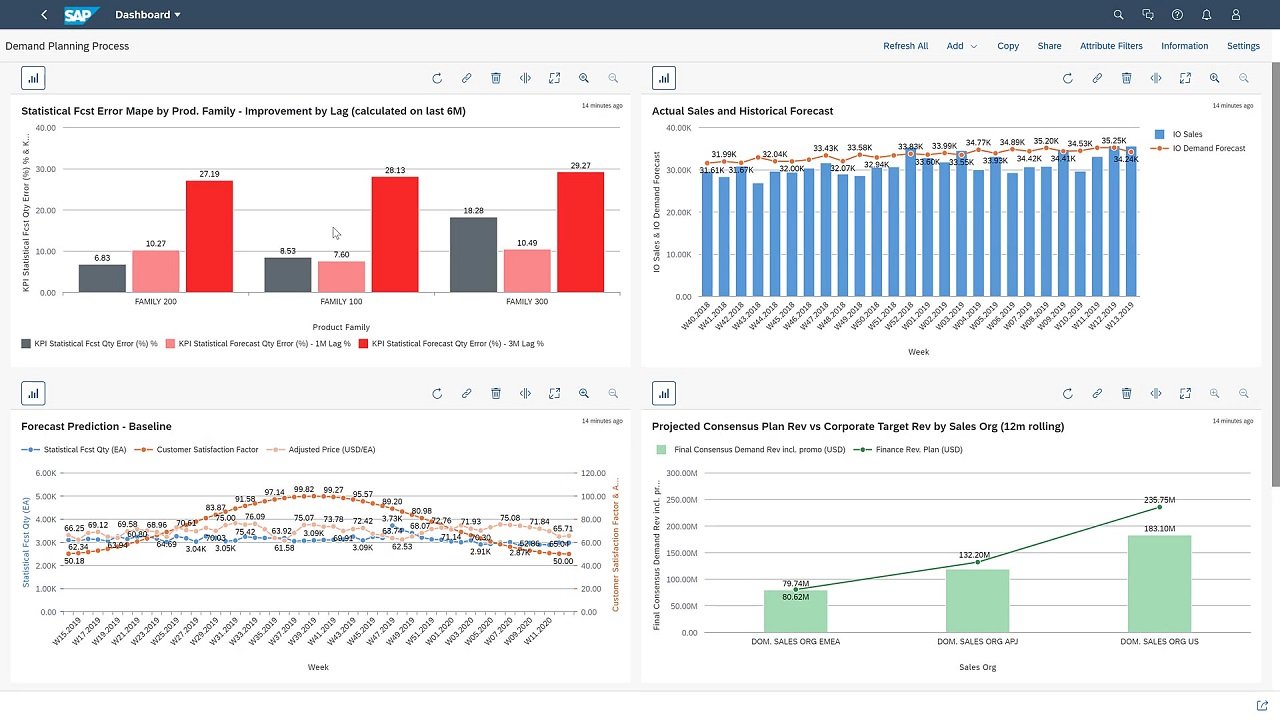

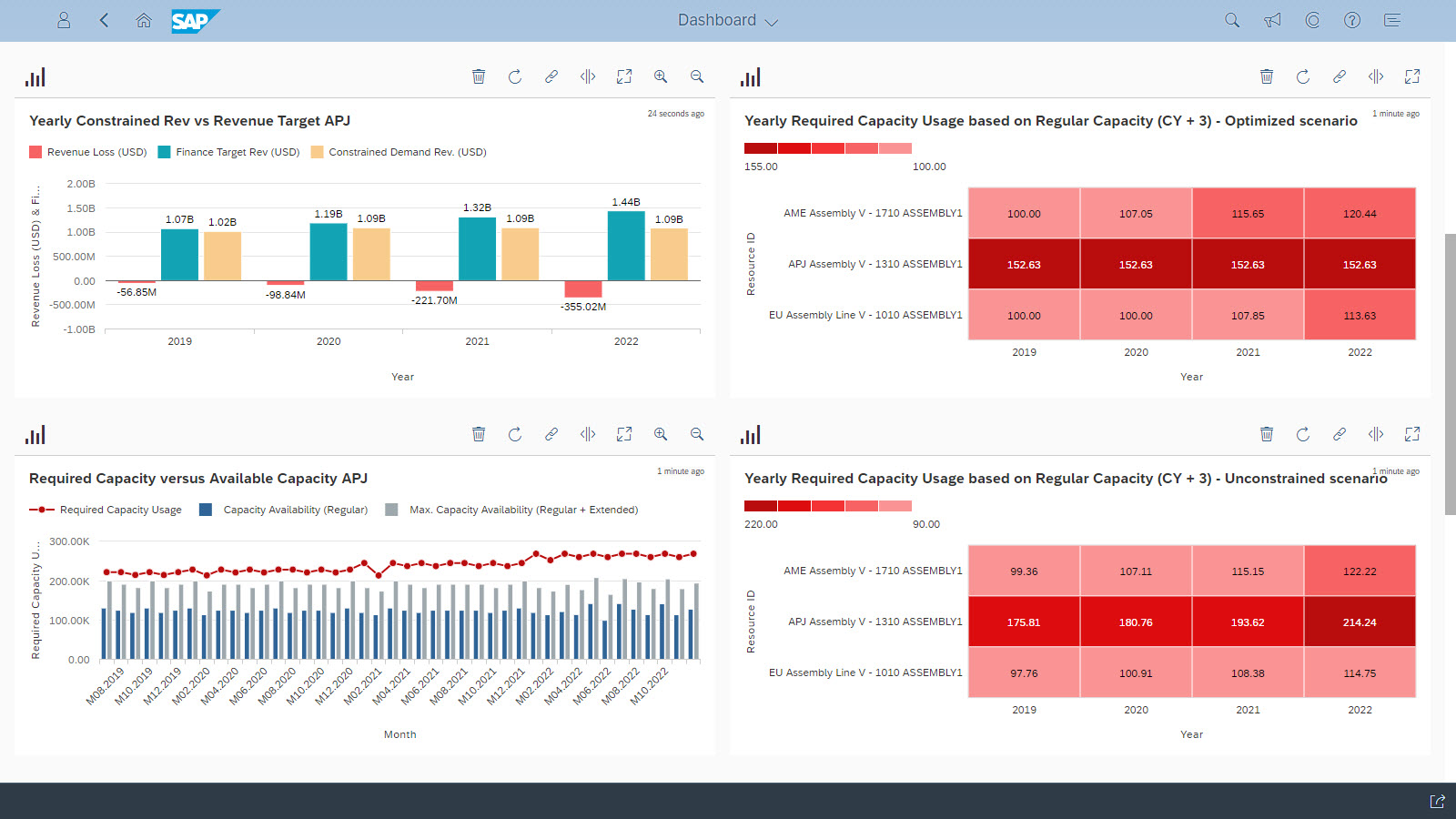

Consider production capacities, inventory levels, lead time, and supplier constraints to create optimal supply plans, meeting customer demand while minimizing costs and maximizing resource utilization.

-

3.

Optimize your inventory levels for each product SKU at various stages of the supply chain, including raw materials, work-in-progress, and finished goods.

-

4.

Develop an integrated sales and operations plan, allowing your sales, production, finance, and operations departments to collaborate and align on a single version of truth

-

5.

Evaluate various what-if scenarios by simulating changes in demand, supply, pricing, promotions to understand the potential impact on key business metrics.

Matching Industries

Key Users of SAP IBP:

-

1.

Supply Chain Managers: oversee end-to-end supply chain operations, optimize processes, improve efficiency, and reduce costs.

-

2.

Demand Planners: generate accurate demand forecasts, identify demand drivers, and improve forecast accuracy.

-

3.

Production Managers: optimize production processes and meet production targets by using tools for production planning, scheduling, capacity optimization, and shop floor control.

-

4.

Inventory Managers: determine optimal inventory levels across the supply chain and reduce stockouts.

-

5.

Logistics Managers: optimize logistics operations and reduce transportation costs.

-

6.

Sales and Operations Planning (S&OP) Teams: develop integrated sales and operations plans, align demand and supply plans, optimize resource allocation across the business.

-

7.

Finance Managers: align financial plans with operational plans and optimize financial performance.

-

8.

Executive Leadership: CEOs, CFOs, and COOs – for strategic decision-making and performance monitoring by getting visibility into key business metrics and strategic insights.

Benchmarking:

Other Solutions

-

AI-driven Demand Forecasting to Reduce Inventory while Boosting Availability

-

Warehouse Management (based on SAP EWM)

-

Digital Logistics and Transportation (based on SAP TM)

-

WMS Audit

TeamIdea provides digital transformation of end-to-end planning processes with full integration of SAP IBP.

Apart from digital transformation we provide the services of development and support of your existing planning solution, based on SAP IBP.